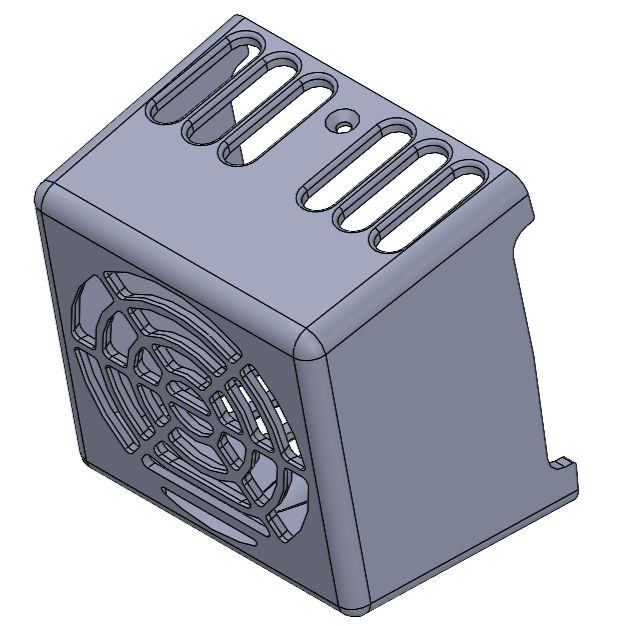

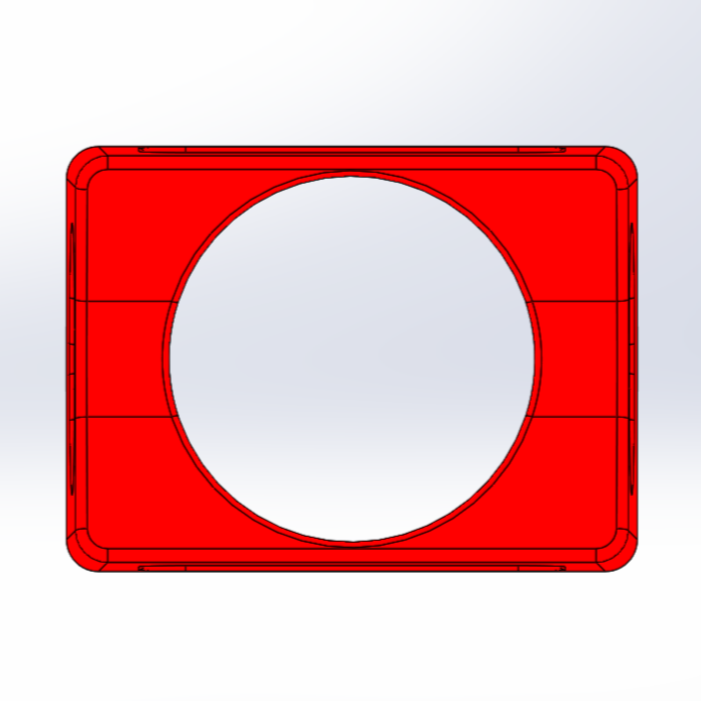

Fan Housing and Lens Cover

Instron | Advanced Video Extensometer | Design

Overview

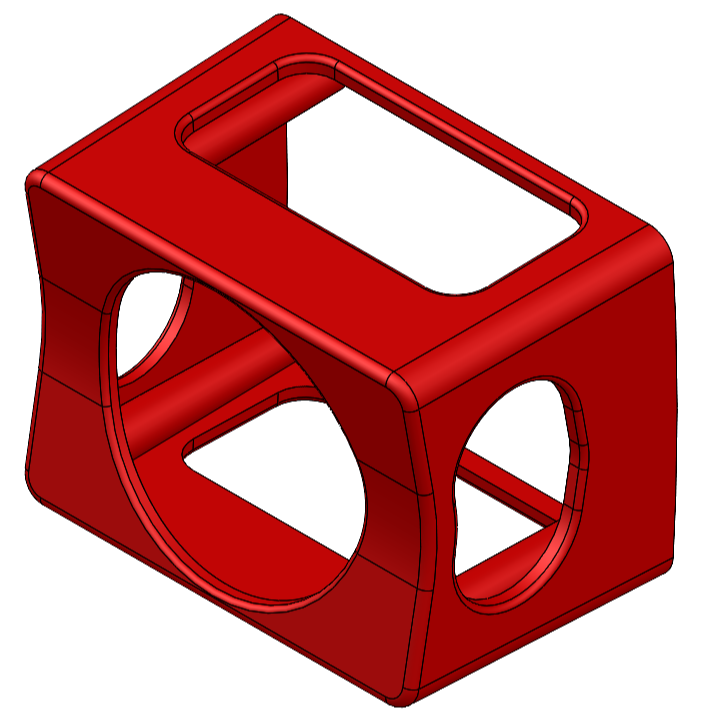

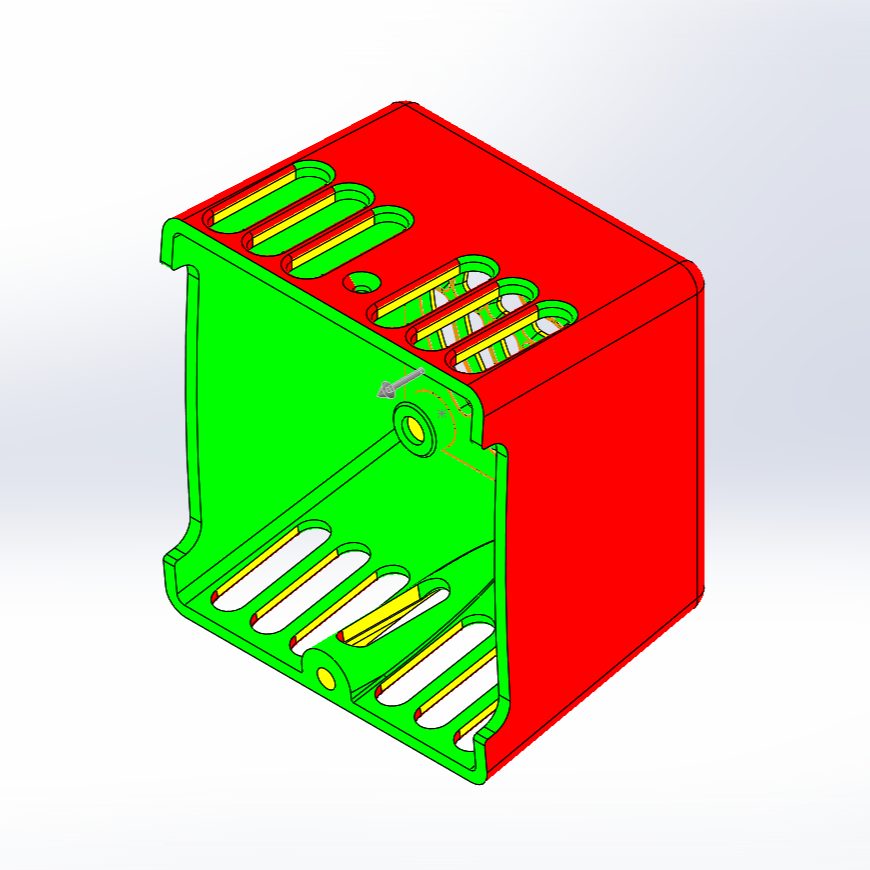

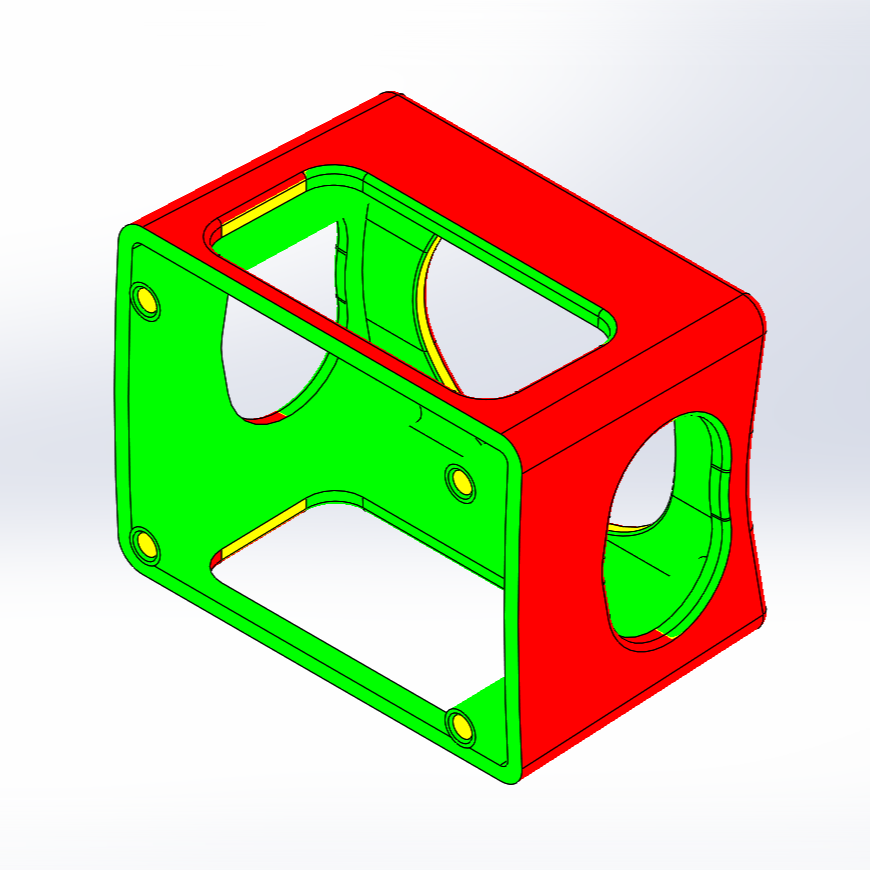

I refined a fan housing and lens cover initially designed and prototyped by the advanced development “AD” team, transitioning it into a production-ready, injection-molded component. The design balanced manufacturability with marketing design language while meeting engineering performance standards and supporting serviceability requirements.

Challenges

Balance AD requirements, including design intent and technical performance.

Ensure manufacturability in collaboration with the injection molding supplier.

Align with marketing design language and aesthetic requirements.

Solutions

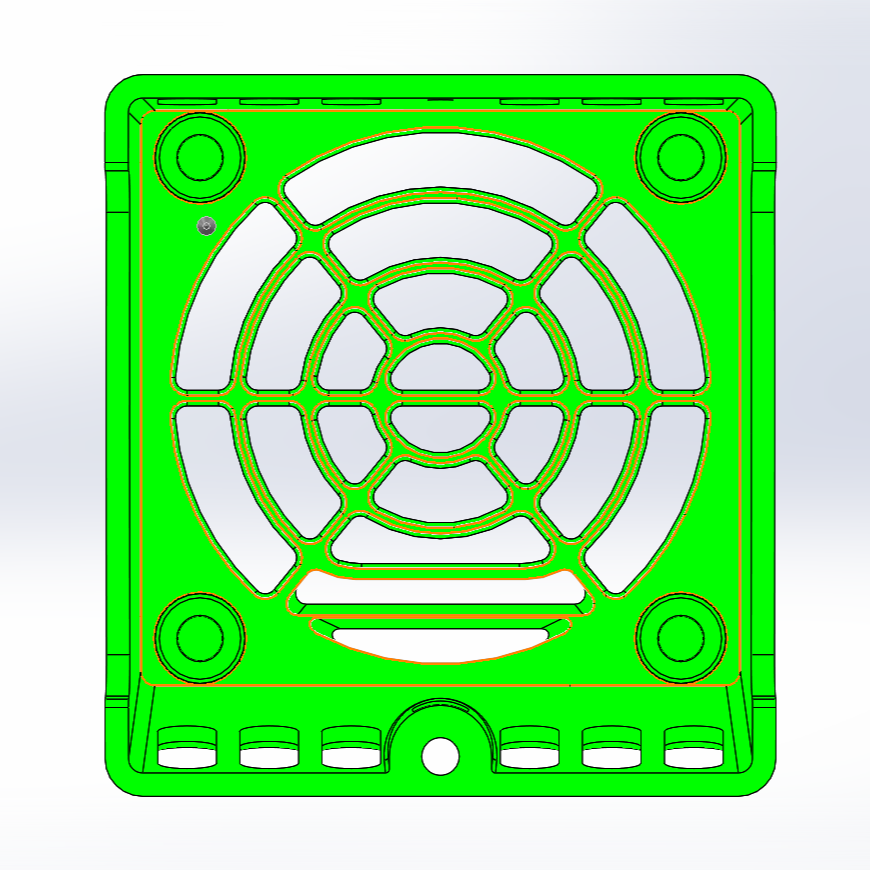

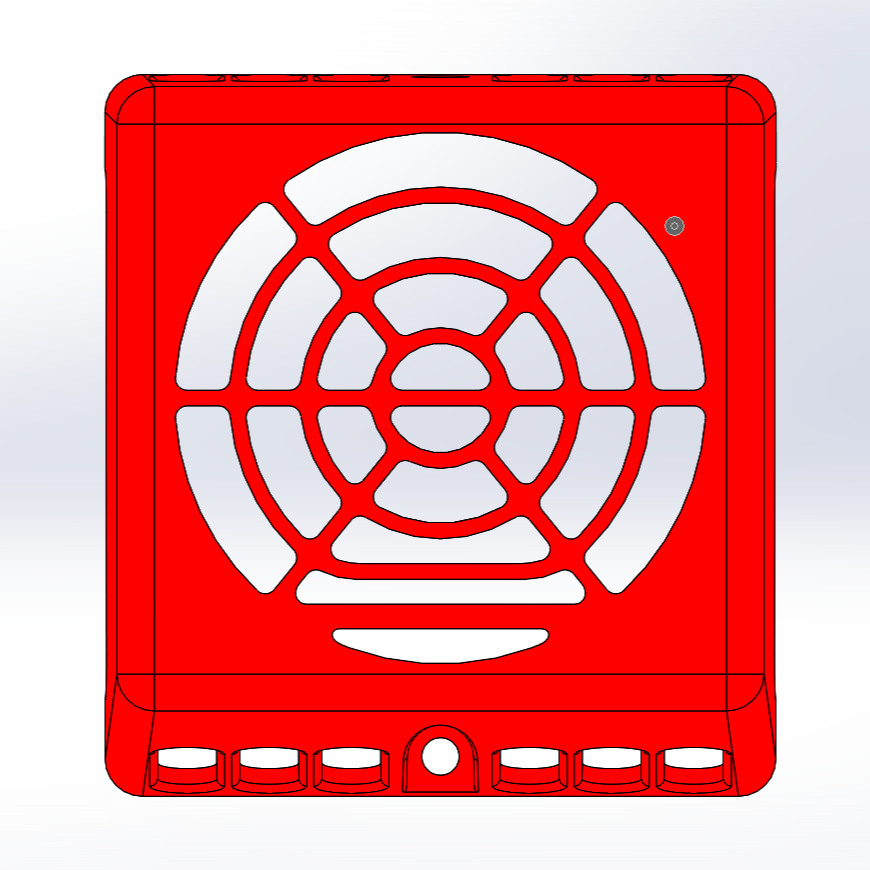

Performance-Driven Airflow: Designed two components to meet required airflow volume and directional performance targets.

Functional Aesthetics: Developed grate and duct geometry that balances visual appeal with airflow efficiency.

Injection-Molded Quality: Engineered parts for injection molding with minimal risk of defects and consistent production quality.

Design & Development

Concept Generation ❖ CAD

Prototyping ❖ DFM ❖ DFA

Analysis & Validation

Design Validation Testing

FEA ❖ GD&T

Manufacturing & Assembly

Material Selection

Supplier Coordination

Communication

Cross-Functional Collaboration

Client Interaction ❖ Documentation

Designed for Injection Molding

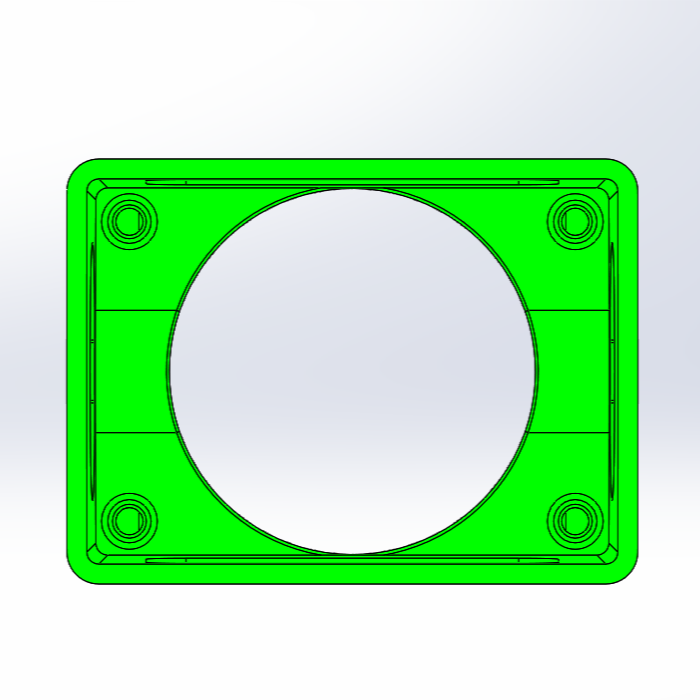

Both components were developed specifically for injection molding, with ongoing collaboration with the manufacturer’s engineering team to reduce part complexity and improve moldability. Early engagement helped minimize tooling cost and eliminate unnecessary secondary operations that could increase production expense. Where challenging features were required, inserts were incorporated to balance manufacturing feasibility with design intent. SOLIDWORKS draft analysis was used to validate draft angles and identify potential molding issues prior to releasing the design.

Iterative, Cross-Functional Design

The design progressed through multiple iterations to balance the technical requirements of the advanced development team—such as airflow performance and vent geometry—with marketing-driven priorities including overall form, user experience, and a simplified design language. Rapid 3D-printed prototypes were used throughout development to evaluate form, fit, and function, enabling stakeholders to assess design changes in parallel with performance considerations. This iterative approach, supported by clear cross-functional communication and testing, ensured that aesthetic refinements did not compromise functionality.

Final Product

Impact:

Production Readiness: Transitioned a 3D-printed prototype into an injection-mold-ready production component.

Improved Assembly & Usability: Simplified assembly and enabled easy customer attachment and removal of the lens cover through magnetic retention.

Technology Enablement: Supported the successful implementation of Instron’s patent-pending CDAT Airflow Technology, improving device strain measurement accuracy.