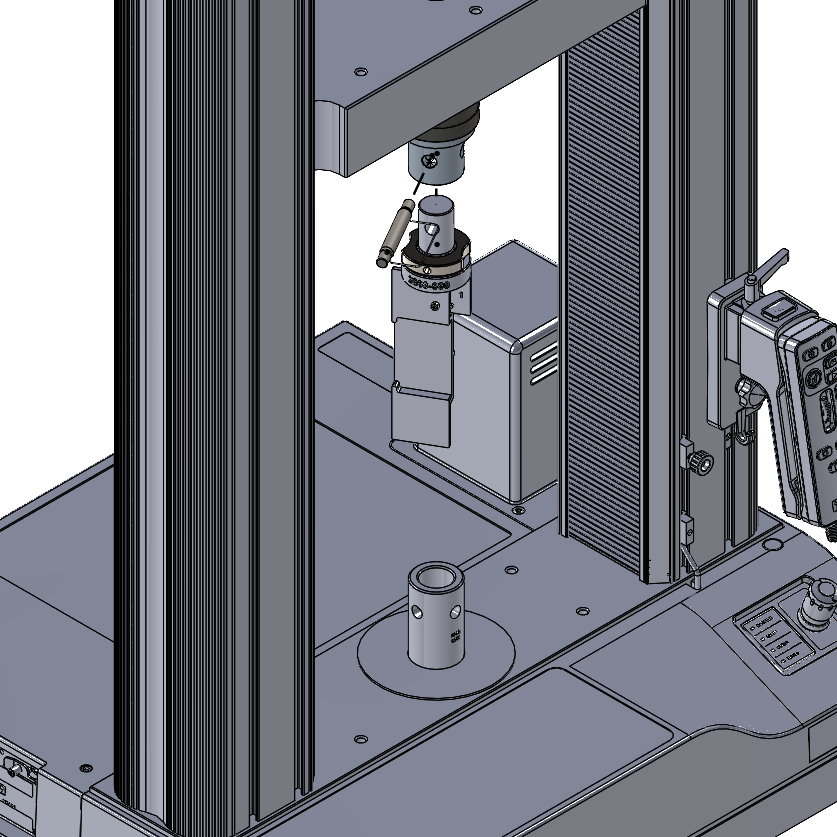

Calibration fixture

Instron | Advanced Video Extensometer | Design

Overview

I designed a replacement fixture to address limitations in an existing setup and improve test consistency. The updated fixture enabled repeatable, trustworthy data collection that directly supported firmware development and helped the extensometer achieve its target ASTM and ISO specifications. By reducing mechanical complexity, minimizing tolerance stack-up, and eliminating unnecessary degrees of freedom, the fixture maintained consistent reference planes throughout the calibration process.

Challenges

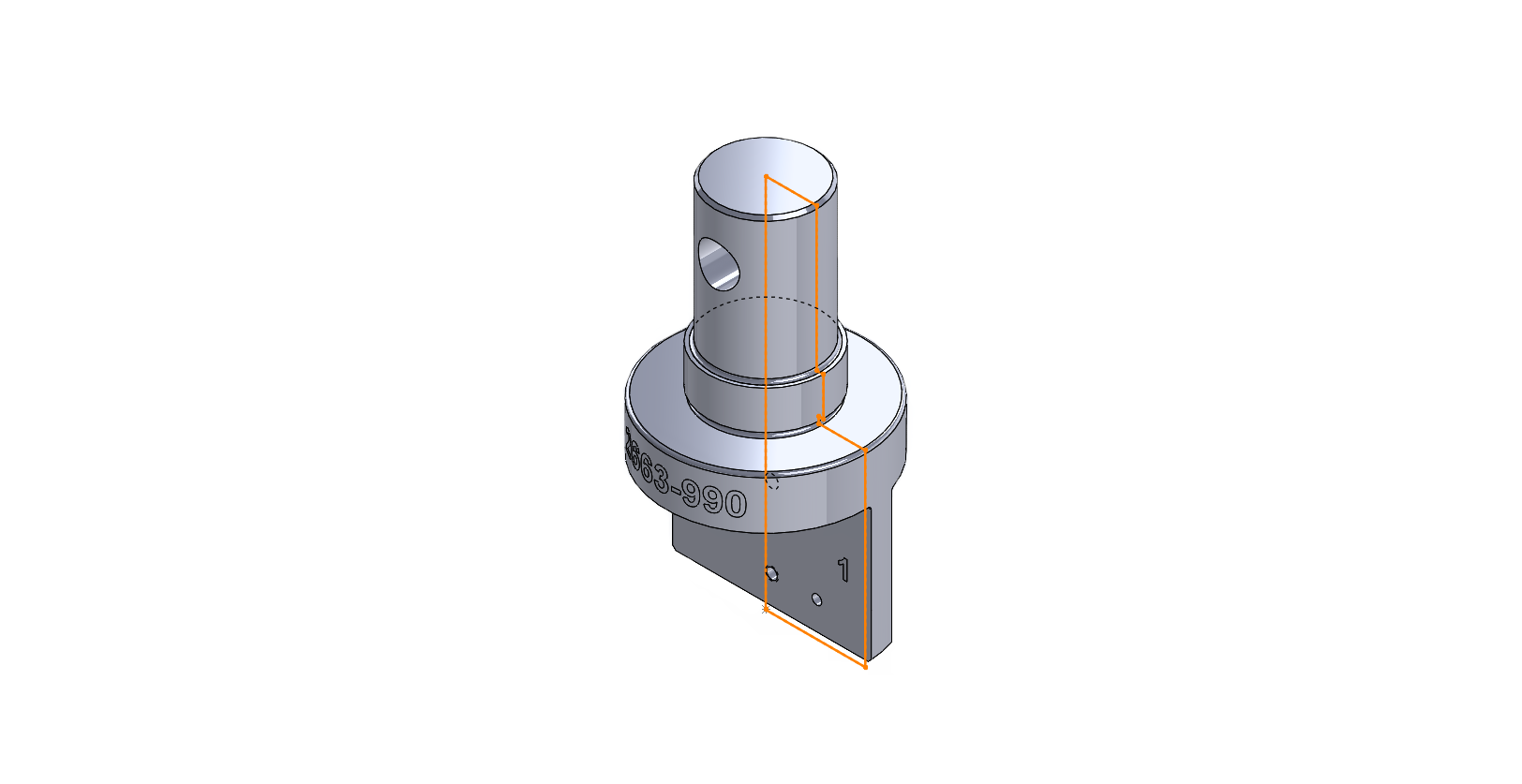

The video extensometer is highly sensitive to planar roll, yaw, and pitch errors.

The existing test setup produced poor repeatability and inconsistent accuracy data.

Solutions

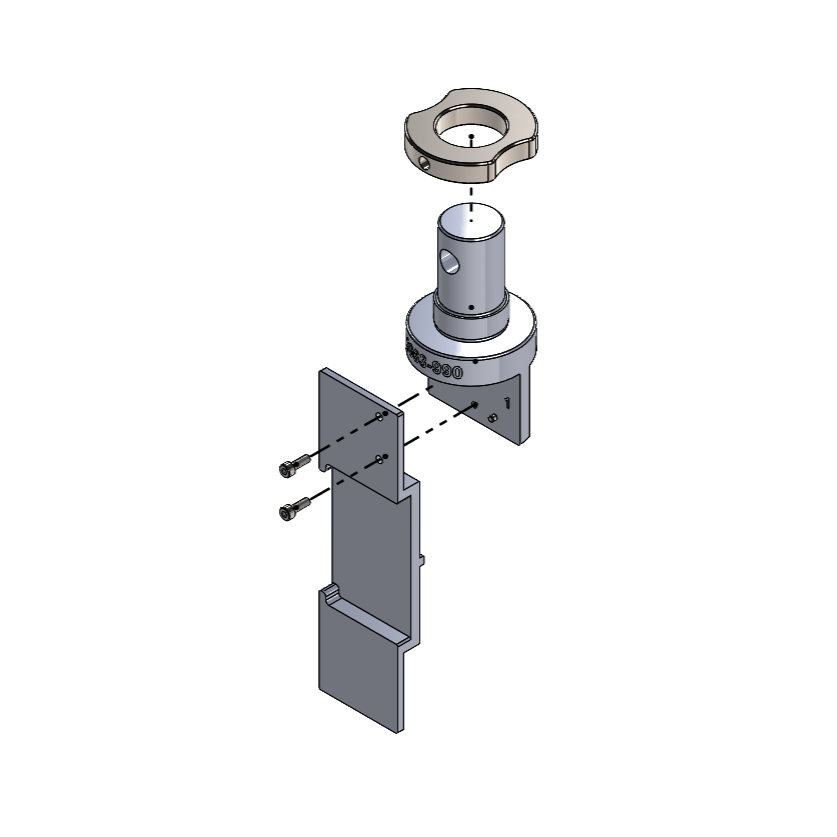

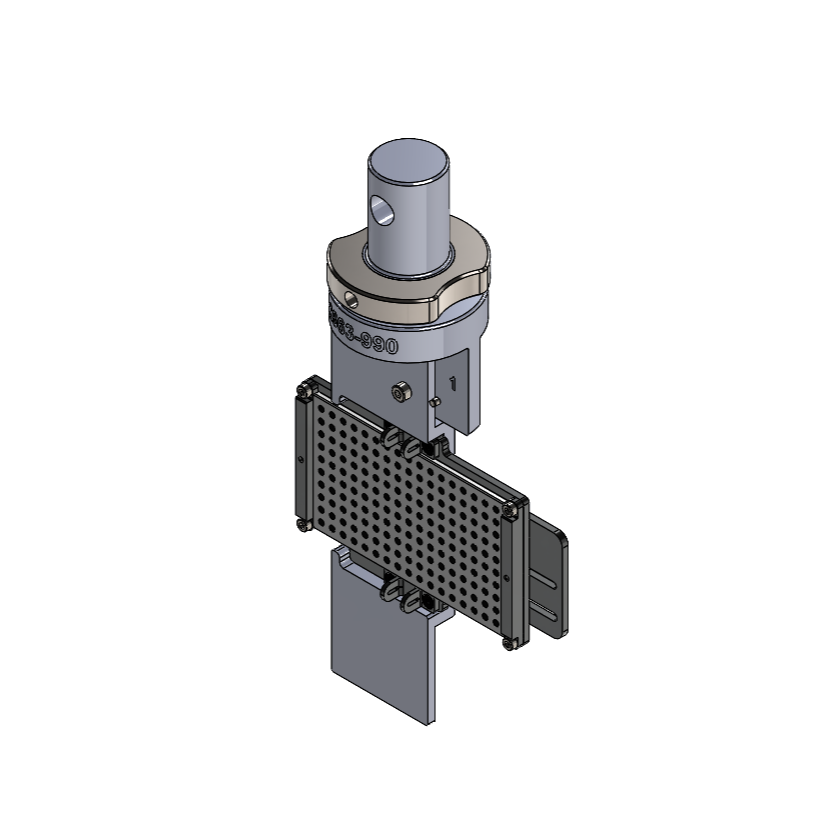

Reduced Complexity: Consolidated the fixture into three unique components, replacing an eight-part design.

Improved Precision: Utilized a single-piece main body to minimize tolerance stack-up and enhance feature control, with geometry optimized for lathe manufacturing.

Calibration Versatility: Incorporated two functional faces to support multiple calibration scenarios within one fixture.

Design & Development

Concept Generation ❖ CAD

Prototyping ❖ DFM ❖ DFA

Analysis & Validation

Design Validation Testing

GD&T

Manufacturing & Assembly

Material Selection

Supplier Coordination

Communication

Cross-Functional Collaboration Documentation

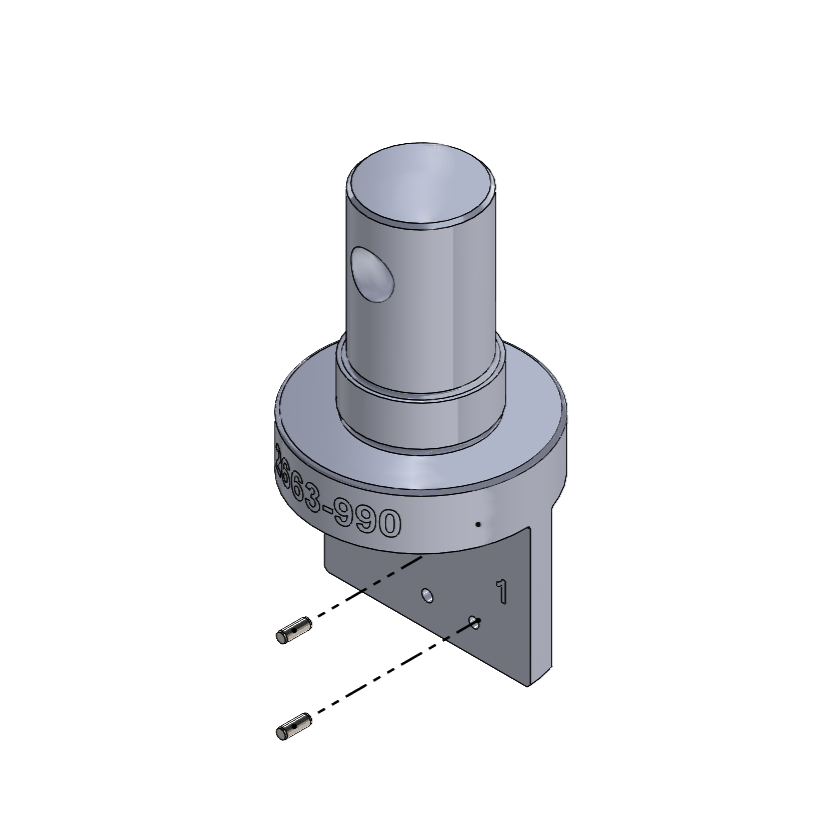

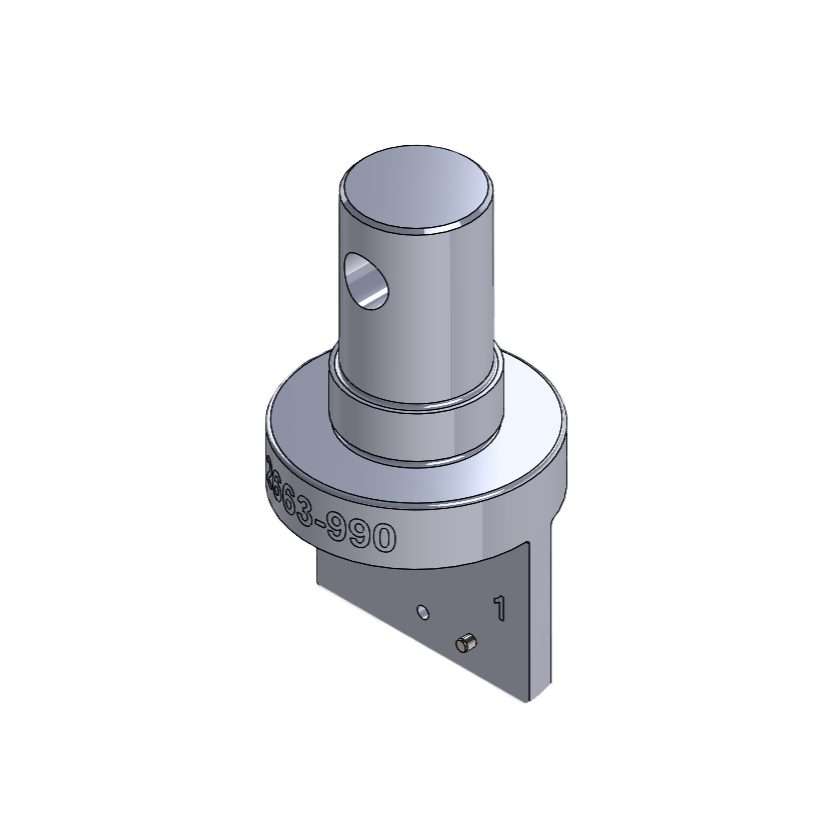

Simplified design

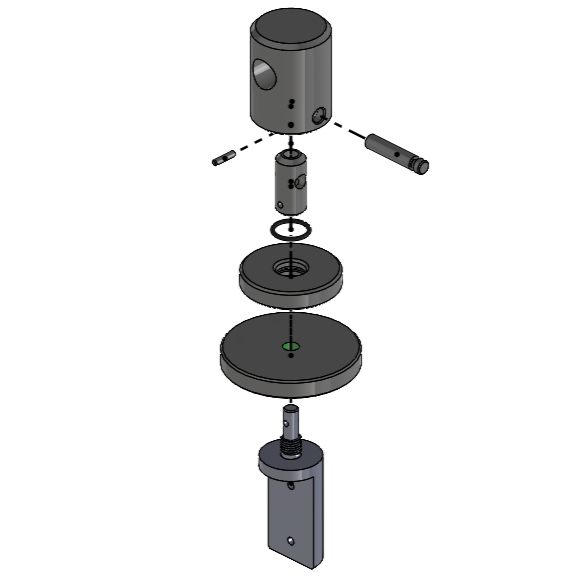

The fixture was reduced from eight components to three, significantly lowering assembly cost and complexity while improving ease of use during setup and calibration. Key functions and reference features were consolidated into a single main body, enabling clear GD&T application to critical reference surfaces. The geometry was also optimized for straightforward lathe manufacturing, supporting precision, repeatability, and cost-effective production.

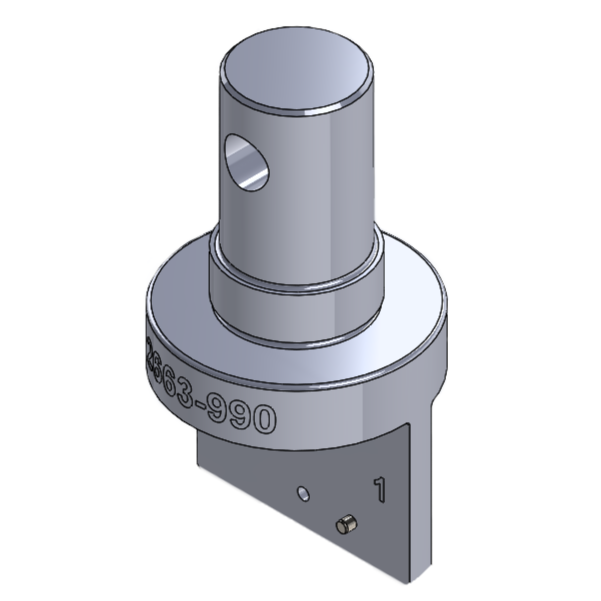

Before

After

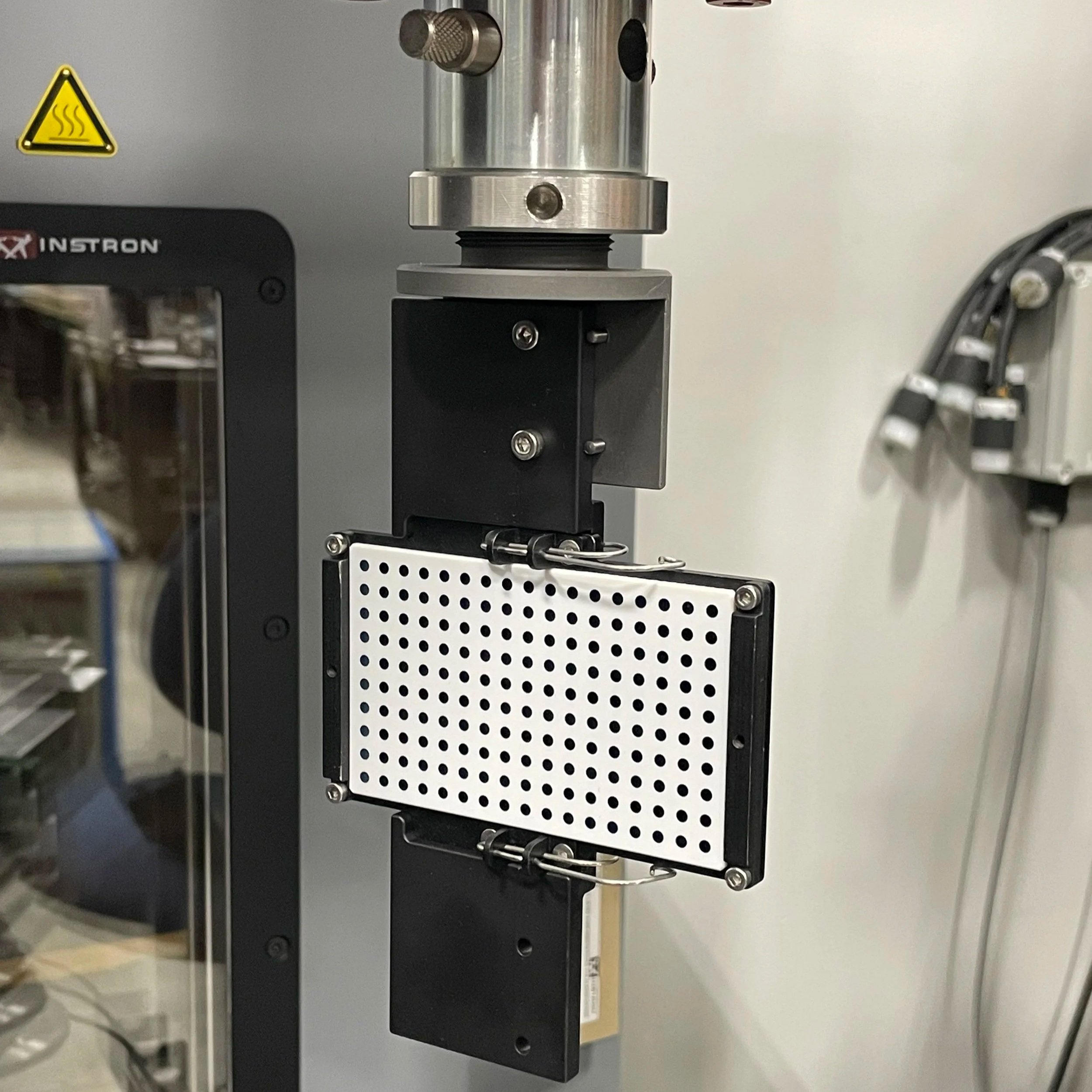

Improved data quality

The previous design relied on an additional adapter, introducing unnecessary tolerance stack-up and extra degrees of freedom that negatively impacted test repeatability. Because the video extensometer is highly sensitive to roll, yaw, and pitch, maintaining a calibration plane that is co-planar with the testing plane is critical for accuracy. The redesigned fixture eliminated these sources of variation, enabling confident testing and providing reliable data that allowed the firmware team to make informed development decisions.

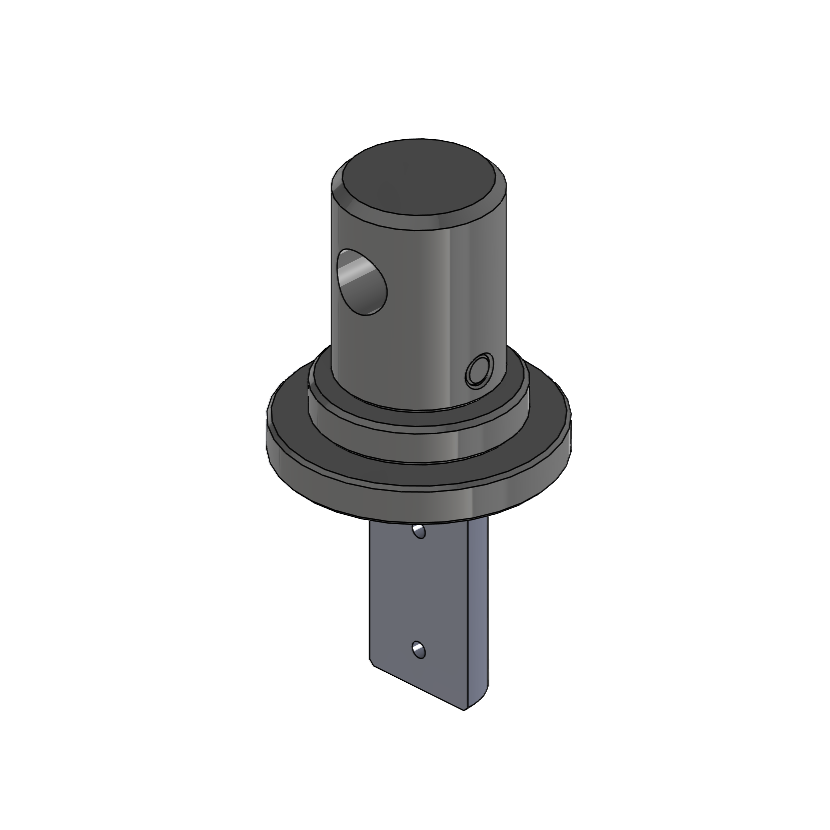

Final Product

Impact:

Component Reduction: Reduced fixture components from 8 to 3 parts (62.5% reduction), lowering cost and assembly complexity.

Improved Accuracy & Versatility: Constrained the calibration plate to remain planar with the testing plane while supporting multiple calibration scenarios within a single fixture.

Faster Development: Eliminated unreliable testing, streamlined V&V, and enabled the firmware team to quickly implement data-driven improvements.