Autoinjector Enclosure

Instron | Autoinjector | Design

Overview

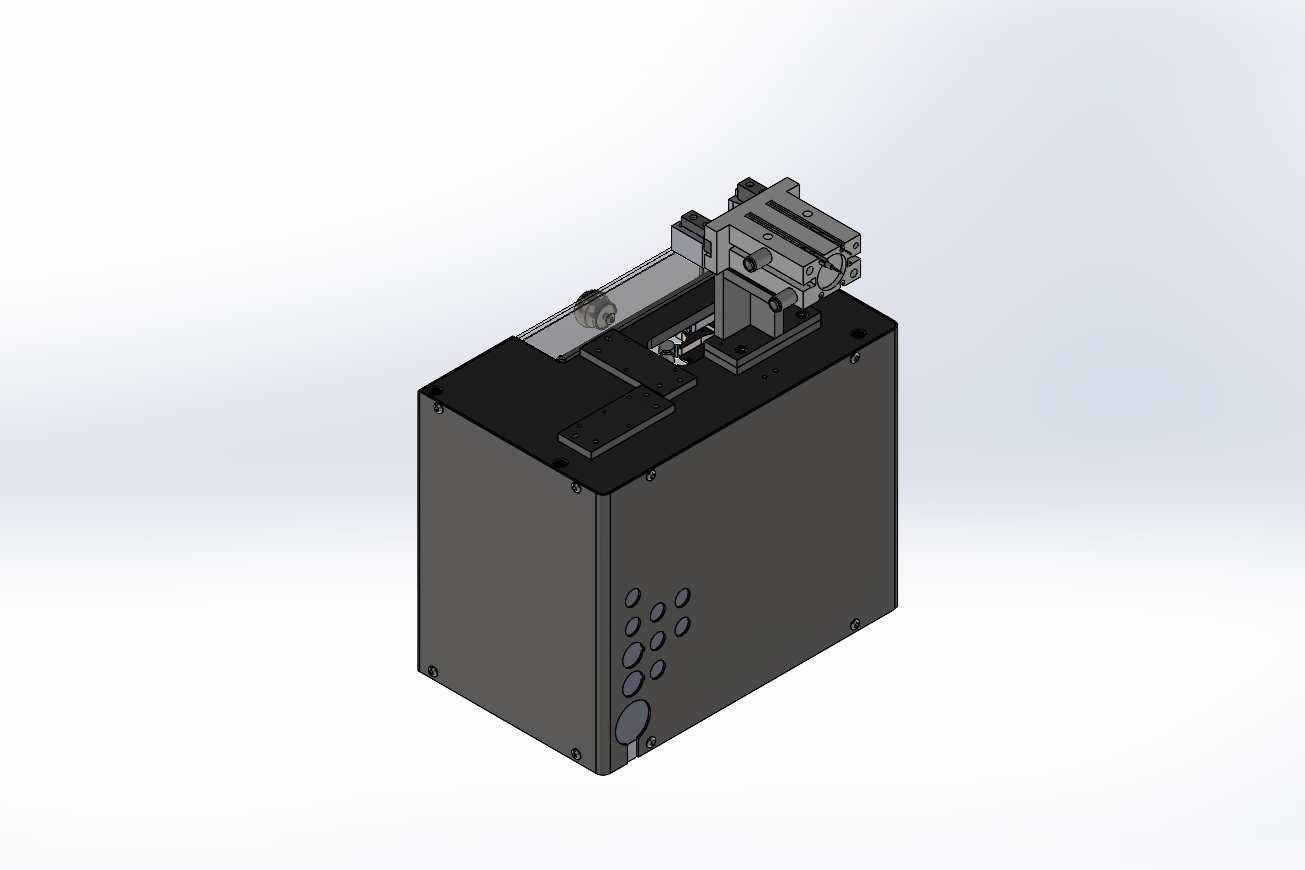

I redesigned the enclosure for the production version of the custom autoinjector, focusing on manufacturability, aesthetics, and serviceability. The new design maintains all functional requirements while significantly reducing the number of unique parts.

Challenges

Field service engineers faced long servicing times due to complex assembly.

Key components were difficult to access during maintenance.

The overall system cost needed to be minimized for production scalability.

Solutions

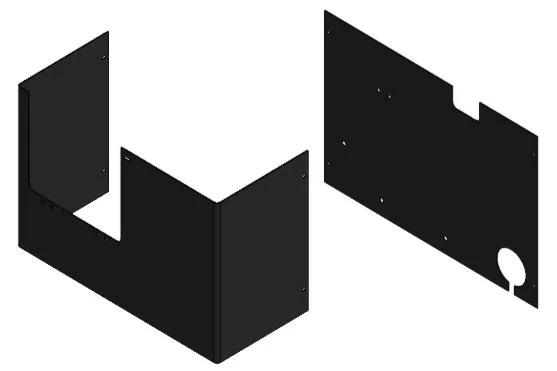

Simplified Assembly: Reduced the enclosure design to just two main sheet metal components, minimizing part count.

Service-Friendly Fastening: Strategically positioned fasteners to balance structural integrity with ease of access, reducing service time.

Improved Accessibility: Redesigned geometry to provide better access to internal components, streamlining maintenance and repair.

Design & Development

Concept Generation ❖ CAD

DFM ❖ DFA

Analysis & Validation

Design Validation Testing

GD&T

Manufacturing

Material Selection

Supplier Coordination

Communication

Cross-Functional Collaboration

Client Interaction ❖ Documentation

Simplified Manufacturing

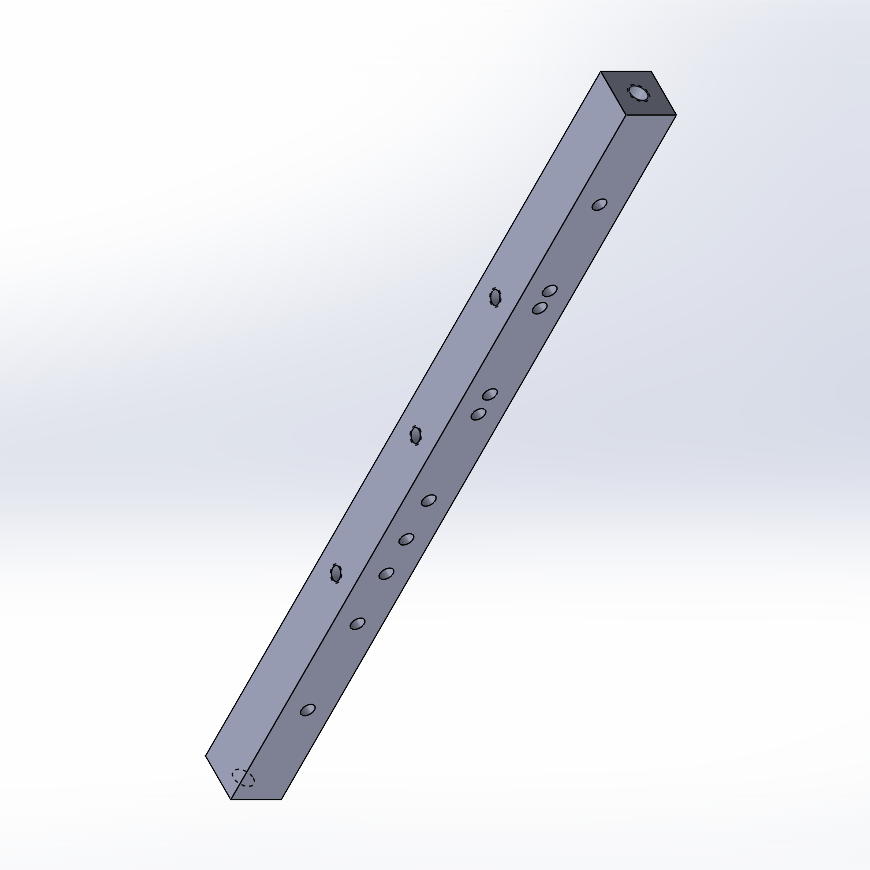

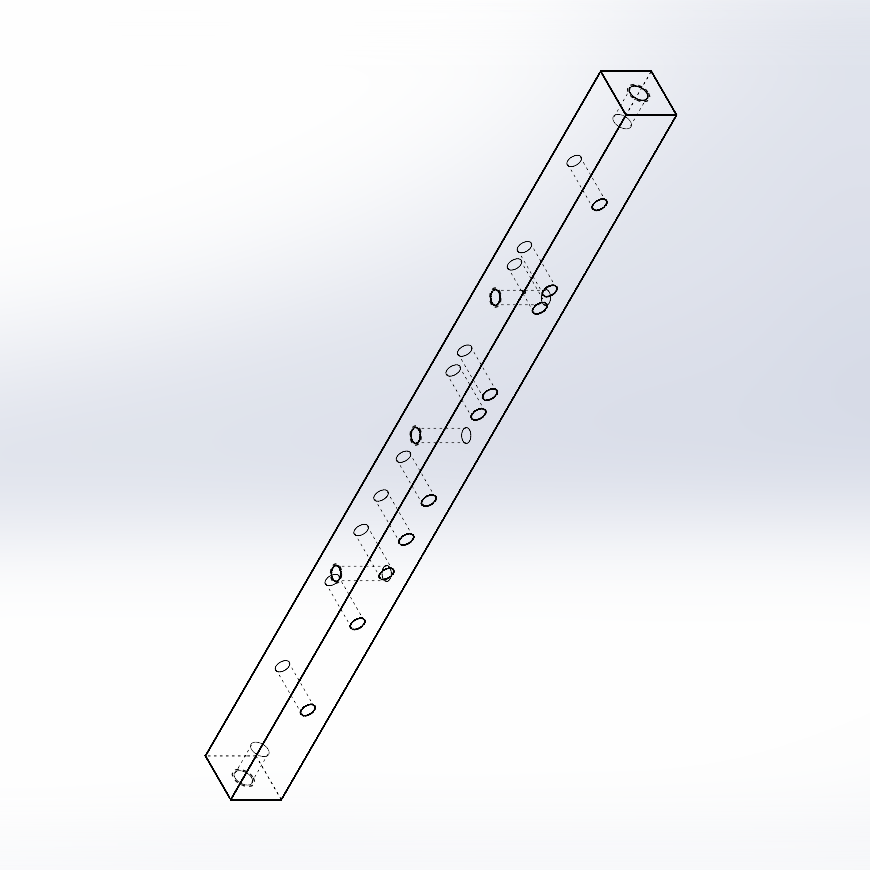

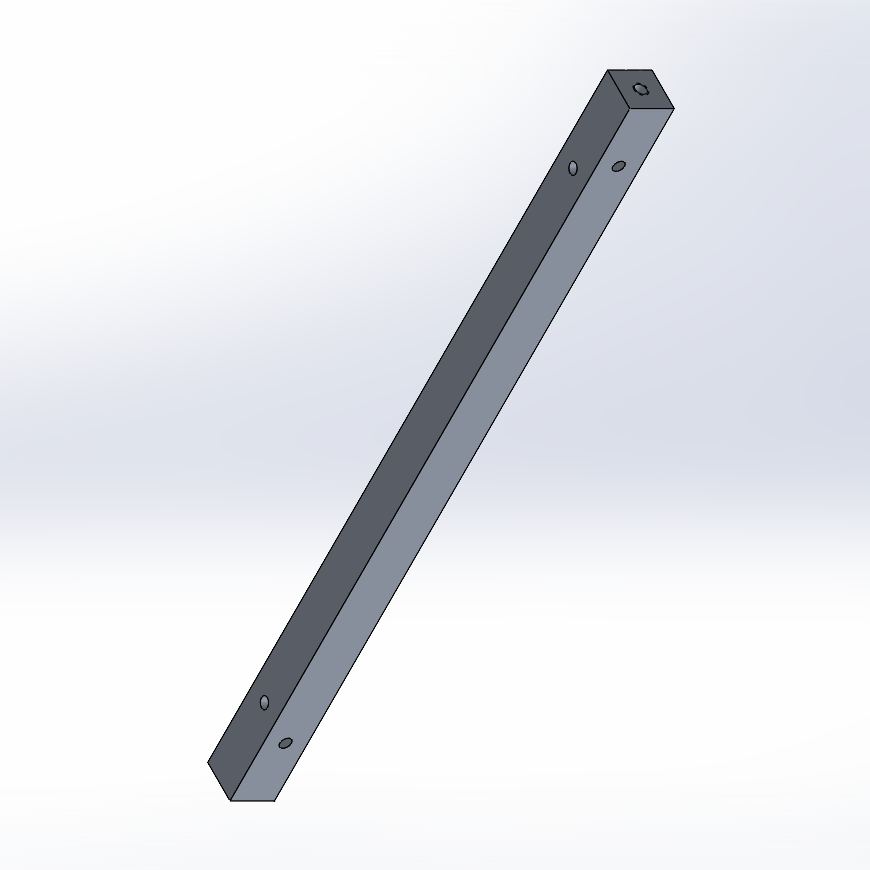

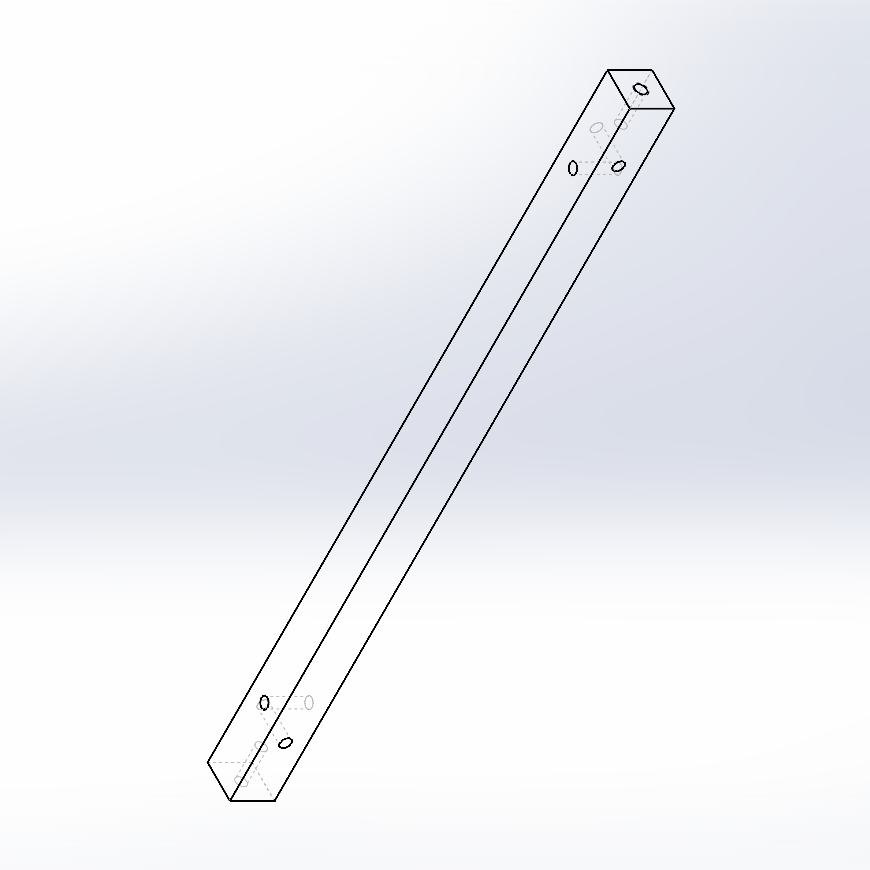

One machined pillar and two sheet metal panels make up the enclosure. The simplified geometry, threaded features, and part count made fabrication and assembly significantly more efficient.

After (Production)

Before (Custom)

Reduced Hardware

Replaced the original three removable panels with just two, improving access while minimizing fastener use. This streamlined servicing time and resulted in a cleaner, more professional appearance.

After (Production)

Before (Custom)

Final Product

Impact:

Reduced Hardware: From 21 screws to 9 screws (57% reduction).

Faster Service: Significantly reduced time required for maintenance and assembly.

Improved Accessibility: Easier access to internal components with fewer panels.

Enhanced Aesthetics: Cleaner, more refined look with minimal visible hardware.